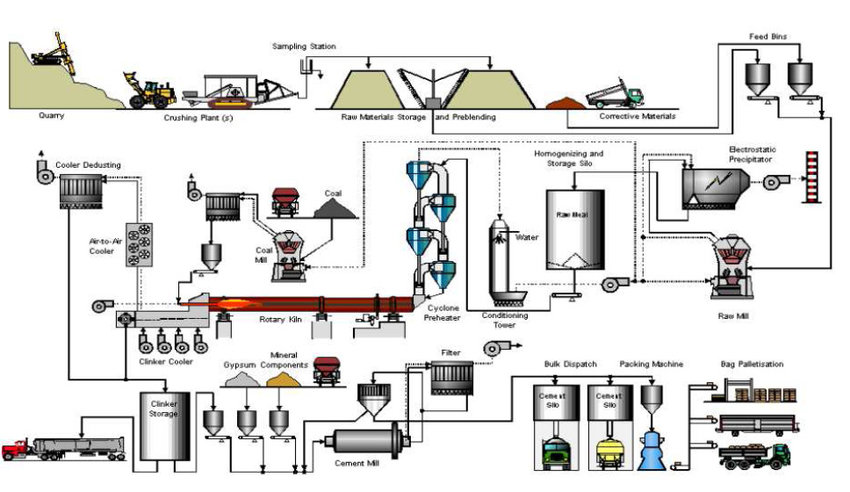

Kiln Process

Thermochemical Reactions in Cement Manufacturing

Kiln Process Thermochemical Reactions

Temperature ranges and chemical reactions in the kiln process

| Process | Reactions | Temperature °C | Temperature °F |

|---|---|---|---|

| Drying/Pre-heat | Free water evaporates | 20 - 100 | 68 - 212 |

| Crystallization water driven out | 100 - 300 | 212 - 572 | |

| Chemical water driven out | 400 - 900 | 752 - 1652 | |

| Calcining | CO₂ Driven out CaCO₃ → CaO + CO₂ |

600 - 900 | 1112 - 1652 |

| Sintering/Clinkering | Formation of Liquid Phase, Formation of alite and belite | 1450 (exothermic) | 2642 (2440 - 2642) |

| Cooling | Crystallization of aluminates and ferrites | 1300 - 1240 | 2264 - 2372 |

Important Note:

Carbon Steel Temperature limit: 800°F (427°C). Refractory lining is required above this temperature.

Generalized Diagram of Long Dry Process Kiln

Dehydration Zone

Free water evaporates, formation of initial compounds

Gas Temp:

450°C / 840°F

450°C / 840°F

Material Temp:

50°C / 120°F

50°C / 120°F

Calcination Zone

Limestone decomposition, CO₂ release

Gas Temp:

800°C / 1470°F

800°C / 1470°F

Material Temp:

600°C / 1110°F

600°C / 1110°F

Clinkering Zone

Formation of C₂S and C₃S, liquid phase formation

Gas Temp:

1200°C / 2190°F

1200°C / 2190°F

Material Temp:

1000°C / 1830°F

1000°C / 1830°F

Cooling Zone

Rapid cooling of clinker, crystallization

Gas Temp:

1750°C / 3180°F

1750°C / 3180°F

Material Temp:

1350°C / 2460°F

1350°C / 2460°F

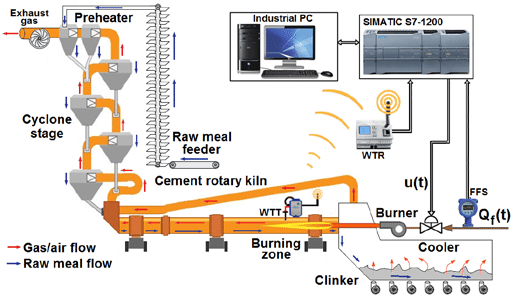

Preheater System

Preheater Tower

Preheaters perform 40-80% calcination

- Multiple stages for heat exchange

- Counter-current gas flow

- Efficient heat recovery system

- Reduces fuel consumption

Precalciner

Precalciners perform 70-96% calcination

- Higher calcination efficiency

- Separate combustion chamber

- Reduces kiln thermal load

- Increases production capacity

Factors Affecting Calcination

The difference between preheater and precalciner performance depends on:

- Number of preheater stages

- Type of calciner design

- Available kiln length

- Fuel type and quality

Rotary Kiln Specifications

Rotary Kiln

Key Components

Physical Structure

- Thick steel cylinder lined with refractory materials

- Diameter: 3m to 8m

- Length: 30m to 200m

- Mounted on roller bearings

- Rotates about its own axis at specified speed

Fuel Types

- Powdered coal

- Fuel oil

- Natural gas

- Alternative fuels (waste-derived)

Operating Temperature:

Up to 1500°C in the hottest zone

Physical and Chemical Changes in the Rotary Kiln

150°C

Limestone loses water in its combination

450°C

Clay decomposes

2SiO₂·Al₂O₃·2H₂O → 2SiO₂ + Al₂O₃ + 2H₂O ↑

650°C

Magnesium carbonate decomposes

MgCO₃ → MgO + CO₂ ↑

950°C

Calcium carbonate decomposes

CaCO₃ → CaO + CO₂ ↑

1250°C

20-30% of raw materials become slurry, clinker balls start to form

Final Step

Grinding clinker with 2-3% gypsum to produce cement

Clinker Cooling Process

Cooling Requirements

Moderate rate of cooling results in higher strength clinker.

Stage 1: Rapid Cooling

From 1200°C to 500°C in approximately 15 minutes

Stage 2: Slow Cooling

From 500°C to normal atmospheric temperature in approximately 10 minutes

Rate of Cooling Influences:

- The degree of crystallization

- The size of the crystal

- The amount of amorphous materials present in clinker

Clinker Cooler

Controlled cooling for optimal clinker quality

Learn More About Cement Production

Explore the complete cement manufacturing process

Cement Process Our Products